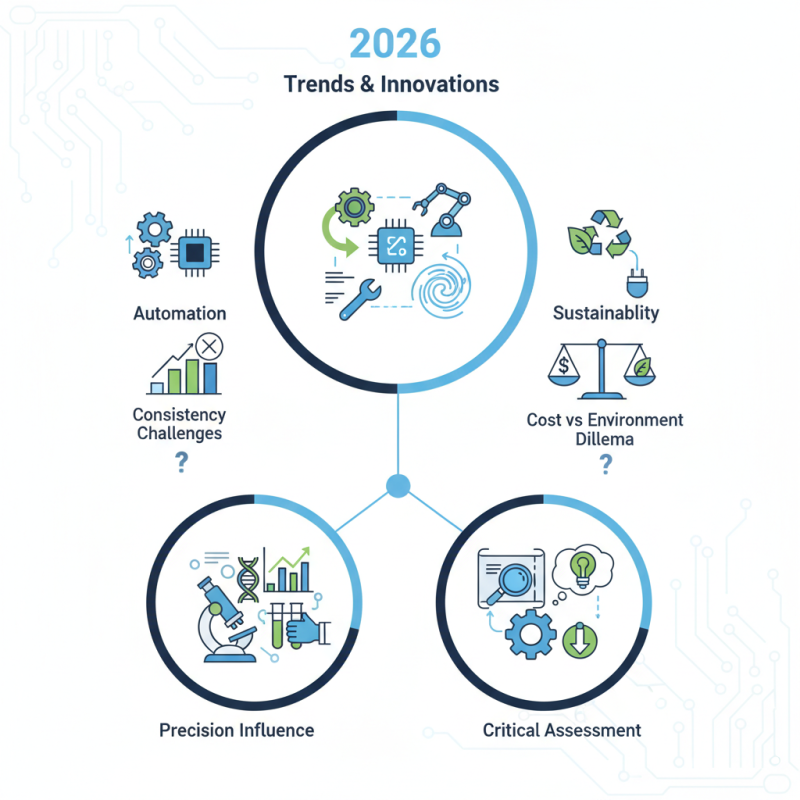

2026 Top Laboratory Sample Pulverizer Trends and Innovations?

In the ever-evolving world of laboratory equipment, the role of the laboratory sample pulverizer is crucial. Industry expert Dr. Emily Tan once noted, "The precision of sample pulverizers can significantly influence research outcomes." As we approach 2026, various trends and innovations are reshaping this field.

The focus on automation is growing. Many new models now feature advanced technology that streamlines processes. However, not every innovation meets expectations. Some automatic systems struggle with consistency, requiring manual adjustments. This highlights the need for ongoing assessments in design.

Sustainability is another key trend. Manufacturers are working to reduce waste and energy consumption. Even so, integrating such practices remains a challenge. Many companies question the balance between cost and environmental impact. As we explore these trends, it is vital to remain critical of developments in the laboratory sample pulverizer industry.

Emerging Technologies in Laboratory Sample Pulverizers for 2026

The landscape of laboratory sample pulverizers is evolving rapidly in 2026. Emerging technologies are reshaping how samples are processed. One notable trend is the use of advanced motion control systems. These systems enhance precision and reduce sample contamination. They can process diverse materials with varying textures and densities. Laboratories are increasingly adopting these innovations for efficiency.

Another interesting development is the integration of artificial intelligence. AI can analyze pulverizer performance, optimizing settings in real-time. It minimizes human error and enhances consistency. However, implementing AI is not seamless. Staff must be trained to navigate new systems. This transition poses challenges for many labs.

Sustainability is also a key focus. There is a push for eco-friendly materials in equipment construction. Recyclable and sustainable components reduce environmental impact. Yet, some innovations may compromise on energy efficiency. Labs need to balance performance and ecological responsibility. As technologies evolve, the approach to laboratory pulverizers must adapt as well.

Key Trends Shaping the Future of Sample Pulverization in Laboratories

In the landscape of laboratory sample pulverization, several key trends are emerging. Automation is at the forefront, enhancing efficiency in sample preparation. Lab technicians appreciate devices that streamline workflow, reducing manual intervention. This not only saves time but also lowers the risk of human error. In addition, researchers are focusing on precision. High-throughput methods allow for rapid analysis and consistent results. Laboratories are increasingly adopting technologies that permit real-time monitoring of pulverization processes.

Sustainability is another crucial trend. Labs are seeking eco-friendly materials and energy-efficient machines. The shift towards greener practices reflects a broader commitment to reducing environmental impact. Innovations in sample pulverization also embrace user-friendly designs. Many laboratories face challenges in training staff on complex equipment. Intuitive interfaces can bridge this knowledge gap, making it easier for new users to operate machinery effectively.

Nevertheless, adapting to these trends isn’t without its issues. As laboratories implement new technologies, they must address the learning curve that comes with them. Balancing innovation and practicality is essential to avoid disruptions in ongoing research. Facilities may find themselves investing heavily without immediate returns. Hence, it is vital for them to evaluate the cost-benefit ratio of such innovations continuously.

Innovations in Material Design for Enhanced Pulverizer Performance

Innovations in material design are transforming laboratory sample pulverizers. Researchers are exploring advanced materials that enhance durability and efficiency. For instance, polymers are now used to reduce wear and tear. This shift impacts the longevity of pulverizers significantly.

The integration of composites is another trend gaining traction. These materials offer better thermal stability and resistance to aggressive chemicals. As a result, the performance of pulverizers improves in demanding environments. However, these innovations come with challenges. Testing new materials can be time-consuming and costly.

Moreover, not all innovations yield immediate benefits. Some new designs may face unforeseen technical issues. Continuous research is crucial to ensure that enhancements truly deliver. Every advancement serves as an inspiration yet requires careful evaluation and adaptation in real-world applications.

Sustainability Practices in Sample Pulverizer Manufacturing

In recent years, the importance of sustainability in manufacturing has surged. The sample pulverizer industry is no exception. Many companies are reevaluating their processes. They aim to reduce waste and energy consumption. Innovative materials are being explored for machine construction. These changes are often met with skepticism. Traditional methods are deeply ingrained in manufacturing culture.

Some manufacturers are now focusing on eco-friendly practices. Recycling metal scraps is gaining traction. Using biodegradable lubricants is another step toward sustainability. However, translating these practices into real results can be challenging. Some machines still rely heavily on energy-intensive operations. This contradiction raises questions about true sustainability.

Engaging the workforce in this shift is crucial. Employees may have resistance to change. Education on sustainable practices can alleviate these concerns. New training programs are being developed, yet their effectiveness varies. Collaboration between teams can lead to innovative solutions. It’s a journey that requires honesty about current practices and a commitment to continuous improvement.

Future Market Dynamics and Demand for Laboratory Sample Pulverizers

The demand for laboratory sample pulverizers is experiencing a notable shift. As industries strive for precision, the need for advanced pulverization techniques is crucial. Researchers and labs are pushing for better efficiency. There is a growing emphasis on eco-friendly materials during manufacturing processes. The shift towards sustainability is palpable.

In laboratories, the dynamics are changing. Traditional methods may not meet current demands. Innovations in technology offer new solutions. For example, automated systems enhance consistency and reduce human error. New designs aim for improved speed and accuracy too. Challenges exist, including the need for regular maintenance. Experts must adapt to evolving material types and sample sizes.

Still, the future looks bright. Rising awareness of testing and quality standards should drive innovation forward. Collaboration between engineers and users can lead to groundbreaking developments. Market dynamics suggest an upward trend in demand for smart solutions. Overall, this industry is on the verge of exciting transformations. More analysis and adaptation will be necessary to stay ahead.