How to Choose the Right Wire Mesh Weaving Machine?

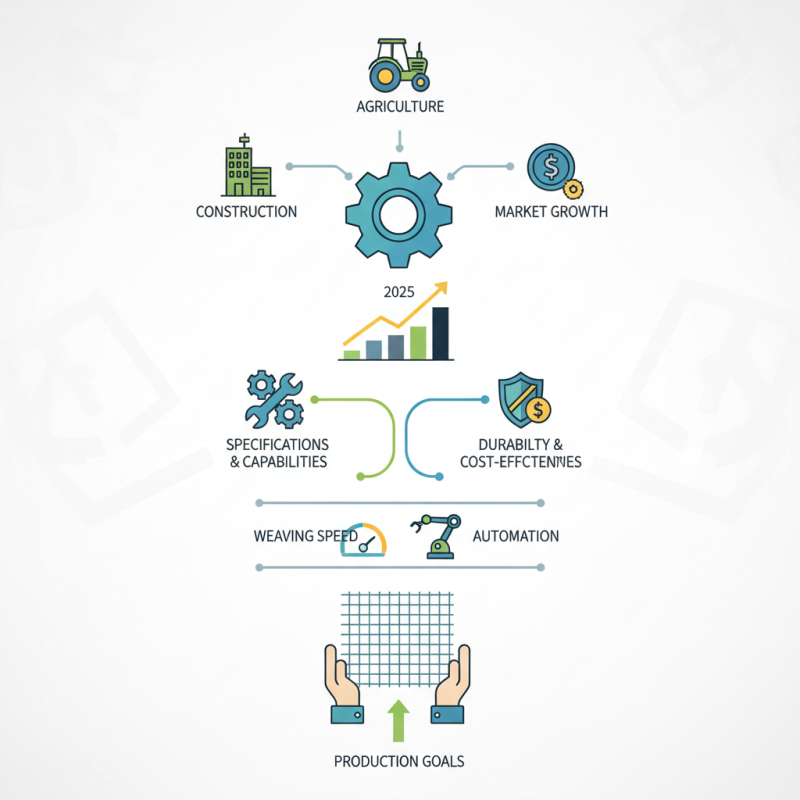

Choosing the right wire mesh weaving machine is crucial for various industries, from construction to agriculture. Reports indicate that the global wire mesh market is estimated to reach $6 billion by 2025. This growth emphasizes the importance of selecting an efficient machine. Industry expert Michael Smith states, "Investing in the correct wire mesh weaving machine can significantly enhance production efficiency."

Understanding the specifications and capabilities of each model is essential. Not all machines are created equal. Some may lack the flexibility to handle diverse mesh types. Furthermore, maintenance costs can vary widely. Companies need a machine that balances durability and cost-effectiveness. Looking for these factors can often lead to missed opportunities or increased expenses.

A detailed assessment of machine features, including weaving speed and automation, is necessary. Some establishments overlook their unique needs in pursuit of the latest technology. This can result in choosing an unsuitable machine. Careful consideration will ensure that the selected wire mesh weaving machine aligns with production goals.

Understanding Wire Mesh Weaving Machines: A Comprehensive Guide

When choosing a wire mesh weaving machine, it’s crucial to grasp the basics. These machines vary significantly in terms of design and functionality. Understanding their mechanisms can improve your decision-making process. Consider the types of meshes you need and the machine's capabilities. Some are better suited for fine meshes, while others can handle heavier materials.

Pay attention to the operational ease. Some machines may require specialized training, which can increase costs. Evaluate your workforce’s skill level. A machine may have advanced features but could be challenging to operate. Getting feedback from current users can provide insights into common issues.

Examine the maintenance needs of the machines. Some machines require frequent checks, while others are more reliable. A machine that demands constant repairs can disrupt production. Reflecting on these aspects can help you choose wisely. Balancing features, costs, and user feedback is essential for a sound investment in wire mesh weaving equipment.

How to Choose the Right Wire Mesh Weaving Machine? - Understanding Wire Mesh Weaving Machines: A Comprehensive Guide

| Feature | Description | Importance |

|---|---|---|

| Machine Type | Various types including shuttle, shuttleless, and Jacquard weaving machines. | Determines the weaving method and complexity of patterns. |

| Wire Diameter | Range of wire diameter supported by the machine. | Affects the strength and versatility of the wire mesh produced. |

| Weaving Speed | Measuring the production speed of the machine. | Impacts productivity and efficiency in production lines. |

| Control System | Manual or automatic controls for machine operation. | Influences ease of use and precision of the weaving process. |

| Maintenance | Complexity and frequency of required maintenance. | Affects the longevity and reliability of the machine. |

| Customization Options | Ability to customize machine for specific applications. | Enhances flexibility for different product requirements. |

| Cost | Initial investment and operational costs. | Critical for budgeting and determining return on investment. |

Types of Wire Mesh Weaving Machines: Pros and Cons

When choosing a wire mesh weaving machine, factors like type, production capacity, and intended application are crucial. Common types include plain weave, twill weave, and Dutch weave machines. Each has its own set of advantages and disadvantages.

Plain weave machines are versatile and user-friendly. They work well for various mesh sizes and materials. However, their production speed may be lower than advanced models. Twill weave machines produce stronger and demure patterns. They are suited for heavy-duty applications but can be more complex to operate.

Dutch weave machines are excellent for fine filtration needs. They offer superior strength and durability. Yet, these machines often require higher initial investment. A trade-off exists between technical complexity and operational ease.

Tips: Consider the mesh specifications required by your projects. That ensures you're investing in the right machinery. Remember, the choice can affect your overall production efficiency.

A study from the Global Wire Mesh Industry Report noted a 20% increase in demand for specialized weaving machines last year. This signals a shift toward customization and efficiency. Reflect on your operational goals before committing to any specific type.

Key Features to Consider When Choosing a Weaving Machine

Choosing the right wire mesh weaving machine involves understanding key features that meet your production needs. Start by considering the machine's weaving capacity. This refers to the maximum width and speed it can handle. A machine with higher capacity can boost your output but could be more complex to operate.

Next, look into the material compatibility. Different machines work best with specific types of wire. If your production varies, it may limit your options. Think about the durability of the machine as well. A sturdy build ensures longevity but can be heavy and harder to relocate.

Finally, assess the control features. A user-friendly interface can be a huge advantage. Complicated settings may lead to mistakes. Pay attention to maintenance requirements as well. Frequent breakdowns can disrupt production. Reflect on how often you can maintain the machine. Choose wisely to avoid common pitfalls.

Choosing the Right Wire Mesh Weaving Machine: Key Features Comparison

Assessing Production Capacity and Efficiency in Weaving Machines

When selecting a wire mesh weaving machine, assessing production capacity and efficiency is paramount. The correct machine can significantly influence output levels. Industry reports indicate that machines with operational speeds of over 100 meters per minute can increase production efficiency by up to 30%. However, choosing a high-speed machine also involves considerations. A fast machine may require more maintenance. This could slow down production if issues arise unexpectedly.

Additionally, consider the type of materials used. Some machines handle certain wire gauges better than others. For example, a recent study highlighted that machines designed for fine wires experience a 15% drop in performance when using thicker materials. It’s crucial to match the machine's specifications with the intended application. Efficiency isn't just about speed; it also encompasses the consistency and quality of the output.

Moreover, reflect on the production environment. Machines are rated for specific capacities under ideal conditions. Yet, actual conditions often vary. Environmental factors, like humidity and temperature, can affect a machine's performance. There is no one-size-fits-all solution. Evaluating your production needs is vital. Identifying potential bottlenecks in your current operations can lead to informed decisions when selecting the right weaving machine.

Cost Analysis: Budgeting for Your Wire Mesh Weaving Machine

When budgeting for a wire mesh weaving machine, consider the initial costs. Prices vary widely based on features and capabilities. A basic machine may be affordable, but it might lack essential functions. Investing in quality often pays off in the long run. Analyze what you need and what you can compromise on.

Next, think about ongoing costs. Maintenance and repairs can add up. Are you prepared for unexpected expenses? These costs could offset savings from choosing a cheaper machine. Evaluate warranties and support services. They can impact your budget significantly.

Lastly, don't forget about training. Operating modern machines typically requires expertise. Budgeting for training can seem like an extra burden. However, well-trained staff can lead to greater efficiency. It's worth investing time and money in this aspect for future gains.